(Brandon Benedict, Halo Custom Guitars)

An instrument neck made of wood is subject to the environment it’s in. Whether it’s hot, cold, humid, dry, etc. the wood reacts. Follow that with your string tension, the natural ways wood rests, the strengths and weaknesses each piece of wood has and you can see the neck is combating so many variables at once.

(From left to right: non-adjustable truss rod, single-action truss rod, dual action truss rod. Photos from stewmac.com)

The introduction of the non-adjustable truss rod helped the neck remain stiff against string tension. Following this, single-action truss rods enabled us to control the amount of relief we could remove ourselves. Thereafter, dual action truss rods were introduced to help with back bow in necks and also give us the control of putting more relief in (where a single-action could only remove relief.)

The truth is, a truss rod--no matter which--can only do so much to help us. We expect a lot of work from the truss rod, but it’s doing its best to help the wood of your neck combat the environment and pull of your strings. Wouldn't it benefit from some help?

(Guitar Neck Reinforcement Rods. Photos from stewmac.com)

That’s where guitar neck reinforcement rods come in to assist. Reinforcement rods honestly do as the name suggests: they help the neck become more stiff and have an easier time combating the environment. In turn, this makes the truss rod have a somewhat easier job by not requiring it to be adjusted as frequently against constant changes to temperature and humidity. Because the neck is more stiff, this also helps stabilize the wood as it settles in different environments, helping it stay straight in the long term. The truss rod will work harder against the pull of your strings, but at least it has an ally to help keep that neck as straight as possible!

Here’s how it works:

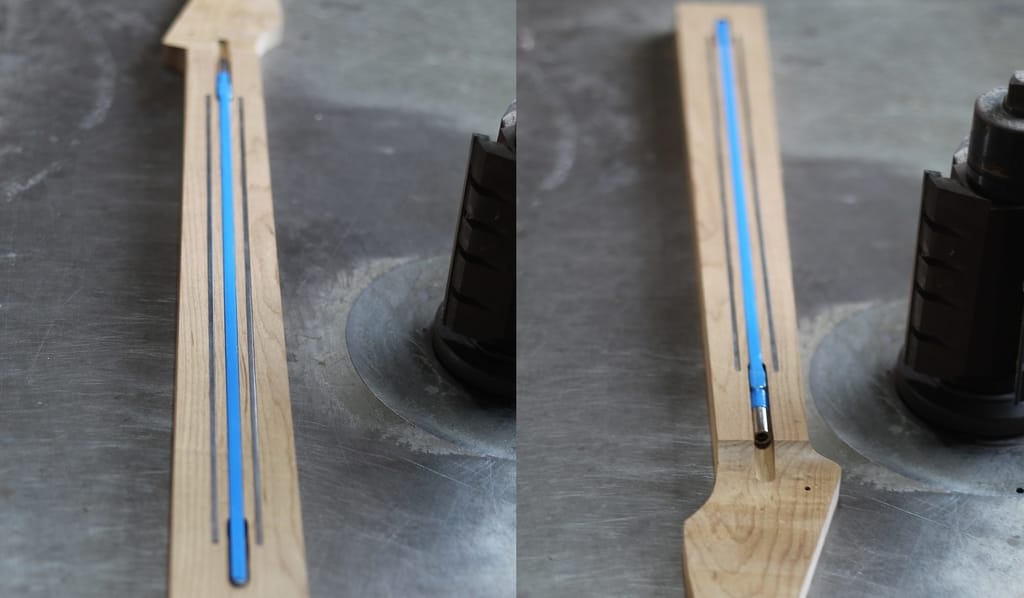

(Guitar Neck Reinforcement Rods Installed)

On both sides of the truss rod channel (located in the middle), more channels are routed. Then the reinforcement rods are placed within these separate channels before the fretboard is installed on top. This firmly seats all of the reinforcement rods next to the truss rod and helps distribute stiffness across the neck. When the truss rod is activated, it moves within it’s channel as the reinforcement rods stay more rigid, following the chosen relief of the neck to help keep even distribution of force.

There are two types of reinforcement rods we use at Halo, and it depends on your preferences.

(Carbon Fiber Guitar Neck Reinforcement Rods. Photo from stewmac.com)

The first is carbon fiber. This material is used due to the weight it possesses and how stiff it can remain. This option also is slightly more flexible than titanium, so adjustments with your truss rod are practically unchanged.

(Titanium Guitar Neck Reinforcement Rods. Photo from stewmac.com)

The second type are metal reinforcement rods. We offer stainless steel and titanium. This material is used for pure strength and rigidity in your instrument’s neck. Although adding more weight, titanium noticeably stiffens the neck. The caveat is that truss rod adjustments are slightly less pronounced.

All of this being said, poor wood selection cannot help maintain a straight neck, regardless of the use of reinforcement rods. We at Halo Custom Guitars strive to make your instruments last a lifetime, so we do our best to make sure that the wood selection is solid. This way if you select reinforcement rods to help your neck remain straighter for the long run, you will have a neck that is tour ready from the mountains to the shores!

Your email address cannot be published. Required fields are marked*

No comments